hardness test on deltaphase ni3nb|ni3nb delta phase : mfg For oil-field applications where delta phase is undesirable for fracture toughness, knowledge and control of the solvus temperature is important for determination of super-solvus solution . O religioso e a mulher mantinham uma relação extraconjugal, e o homem teria incentivado que ela abortasse a criança, mas o bebê nasceu vivo e ela o matou asfixiado. Matheus Facundo 13 de .

{plog:ftitle_list}

WEB18 de fev. de 2024 · Content Getting A no-deposit Harbors Added bonus Prepaid Percentage Actions Zero Lowest Put step three Pound Local casino United kingdom The fresh and you may Common Operators What is Great about Casinos With 5 Lowest Put You ought to as well as give a legitimate photographs ID, such an excellent passport or .

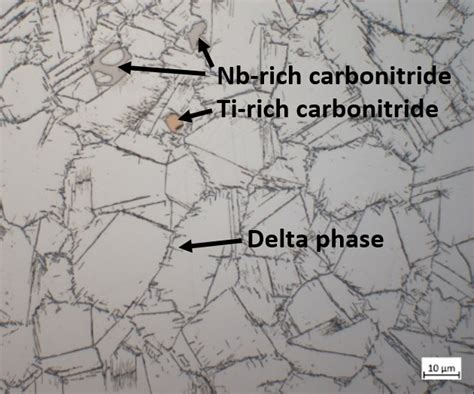

For oil-field applications where delta phase is undesirable for fracture toughness, knowledge and control of the solvus temperature is important for determination of super-solvus solution .It trans-forms into a stable but incoherent δ phase (Ni3Nb) with orthorhombic structure if the alloys is exposed to long ageing time or to temperatures higher than 650 °C or even during . Abstract. The δ-Ni 3 Nb phase is indispensable in achieving the uniform microstructure containing refined grains during the hot-forging process of superalloy 718. The .The most stable Ni3Nb precipitate was the orthohombic delta phase which nucleated at grain boundaries and grew into plates lying on the matrix f 111 3 planes.

The precipitation behaviors of δ phases (Ni 3 Nb) in a nickel-based superalloy are investigated by stress-free and stress aging tests. The effects of aging parameters on the . It has been shown previously that nucleation of delta phase is difficult in a material free of γ ′′ precipitates . We therefore investigated the first stage of delta phase growth by .

They have shown that 0.2-1.5% δ phase do not influence the mechanical properties of aged samples, but yield strength, ultimate tensile strength, elongation, and hardness is influenced by.

It is found that this industry-recommended heat treatment promotes the formation of a significant fraction of the orthorhombic D0a Ni3Nb δ-phase. This phase is known to have . The precipitation of the equilibrium δ-Ni3Nb phase has been studied in two niobium bearing nickel base superalloys—INCONEL 718 and INCONEL* 625—both of which are . DOa is the Strukturbericht designation for δ (Ni3Nb) phase [89]. δ phase cannot increase the mechanical properties (hardness, toughness, ductility) of material at room temperature, and may . The effects of the γ″-Ni3Nb phase on the mechanical properties of Inconel 718 superalloys, with standard heat treatment, hot isostatic pressing + solution treatment + aging, and hot isostatic pressing + direct aging, were .

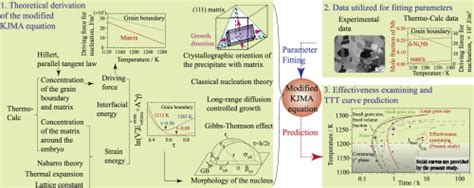

As a result, Vickers hardness test with a load of 5 kg was used for studying phase transformation kinetics based on the Johnson-Mehl-Avrami-Kolmogorov (JMAK) equation (equation (2)) [33][34] [35 . Alloy 718 is an age hardenable, nickel-base alloy used in fuel assembly of Pressurized Water Reactors (PWRs) by virtue of its high strength and resistance to corrosion and stress corrosion cracking. (a) The crystal structure of the γ″-Ni 3 Nb, (b) the 2 × 2 × 1 supercell for calculation, and (c) calculated formation enthalpies of the γ″-Ni 3 Nb phases as a function of composition.E-mail: [email protected] The orthorhombic DOa Ni3Nb delta phase is naturally presented in microstructure of cast or wrought Ni – Cr – Fe base alloy 718. It is a reason of chemical composition heterogeneity. For delta phase formation is a minimum Nb content about 8% needed and temperature above 650°C and higher. . For high frequency .

EVOLUTION OF δ PHASE MICROSTRUCTURE IN ALLOY 718 Sundararaman Mahadevan1, Sachin Nalawade1, Jung Bahadur Singh1, Amit Verma1, Bhaskar Paul2 and Kishore Ramaswamy1 1Structural Metallurgy Section, Materials Group, BARC, Mumbai 4000 85, India; 2Refractory Metals Development Section, Materials Group, BARC, Mumbai 4000 85, India .

The precipitation and dissolution kinetics of the δ-phase were studied in three wrought versions and one spray-formed (SF) version of the nickel alloy, Inconel 718.The precipitation of the equilibrium δ-Ni3Nb phase has been studied in two niobium bearing nickel base superalloys—INCONEL 718 and INCONEL* 625—both of which are hardenable by the precipitation of the metastableγ″-Ni3Nb phase. The morphology and the distribution of precipitates have been examined and the crystallographic orientation relationship between the austenite . @article{Natarajan2017FormationOT, title={Formation of the Ni3Nb delta-phase in stress-relieved Inconel 625 produced via powder-bed laser fusion additive manufacturing}, author={Bharath Natarajan and Ajay Krishnamurthy and Caglar Dogu Emiroglu and Amanda L. Forster and Earl Johan Foster and Christoph Weder and Douglas M. Fox and Jan Obrzut and . Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness Testing. Hardness testing is important for a number of different reasons. The hardness of a material can be a critical parameter in its .

Request PDF | On Jan 1, 2010, A. Verma and others published Evolution of Delta Phase Microstructure in Alloy 718 | Find, read and cite all the research you need on ResearchGate . The δ-Ni3Nb . The high-temperature testing was performed under an argon atmosphere with a flow rate of 5–18 L / h. All tensile tests were performed under a constant strain rate of 6.5 × ASTM E8/E8M-08, Standard Test Methods for Tension Testing of Metallic Materials, ASTM, West Conshohocken, PA, 2009. S. Olovsjö, A. Wretland, and G. Sjöberg, The Effect of Grain Size and Hardness of Wrought Alloy 718 on the Wear of Cemented Carbide Tools, Wear, 2010, 268, p 1045–1052. Article Google Scholar The microstructure and mechanical properties of alloy 718 are highly dependent on heat treatment schedule [7, [11], [12], [13]].While the primary strengthening precipitate in alloy 718 is D0 22-ordered Ni 3 (Nb, Ti, Al) (γ″ phase), the L1 2-ordered Ni 3 (Ti, Al, Nb) (γ' phase) contributes to alloy strength as well. Depending on the ageing time, the γ″ phase can .

The δ-Ni3Nb phase is indispensable in achieving the uniform microstructure containing refined grains during the hot-forging process of superalloy 718.The orthorhombic DOa Ni3Nb delta phase is naturally presented in microstructure of cast or wrought Ni - Cr - Fe base alloy 718. It is a reason of chemical composition heterogeneity.

Aside from the Ni3Nb typ phases, MC, M6C, and M23C6 carbides (M for metallic element and C for carbon) typicall form over the temperature range from 600 °C to 1200 °C [42,43]. . wire and arc .

An Inconel 718 sheet alloy was tested in tension at a temperature of 965°C and an initial strain rate of 10−4s−1 corresponding to the conditions for optimum superplastic deformation.

Inconel 625 alloy is a solid-solution strengthened nickel-based superalloy, widely used in the petrochemical, aerospace, marine, power generation, and nuclear industries due to its excellent high-temperature strength and corrosion resistance [1], [2], [3], [4].Cr, Mo, Fe, and Nb are the representatives of the solid solution strengthening elements in Inconel 625 alloy.

Semantic Scholar extracted view of "A novel approach to investigate delta phase precipitation in cold-rolled 718 alloys" by Z. K. Low et al. . Two in-situ test techniques were used to obtain insight into the isothermal precipitation kinetics of γ″ and γ′ in superalloy 718. . Growth behavior of the δ-Ni3Nb phase in superalloy 718 and .Delta phase (δ) is the stable form of Ni3Nb with orthorhombic crystal structure. It is known that the pres- . sition of testing material and the basic mechanical properties are shown in the Tab.1 and Tab.2. . Hardness HBW 20°C 1474 1238 26 450 650°C 1211 1030 13.5 -

Inconel 718 is widely used because of its ability to retain strength at up to 650∘C for long periods of time through coherent metastable 𝛾 Ni3Nb precipitation associated with a smaller volume fraction of 𝛾 Ni3Al precipitates. At very long ageing times at service temperature, 𝛾 decomposes to the stable Ni3Nb 𝛿 phase. This latter phase is also present above the 𝛾 solvus .

Fogging Testing distributor

Semantic Scholar extracted view of "Experimental Investigation of Delta Phase Precipitation in Inconel 625 Superalloy Aged at 550, 625 and 725 °C" by R. Baldan et al. . (PWHT) on the microstructure, hardness, and corrosion behavior of Inconel 625 weld metal deposited by the Electro . Formation of the Ni3Nb δ-Phase in Stress-Relieved . Fig. 2 (a) represents TEM micrograph of the specimen thermally aged at 650 °C for 50 h, of which hardness corresponds to the highest value. Many small black dots are seen. Its diffraction spots taken from [0 0 1] direction is shown in Fig. 2 (b), where weak extra spots are slightly identified between clear spots from Fe–Ni matrix. A crystalline structure of the γ″-Ni 3 .The precipitation of the equilibrium δ-Ni3Nb phase has been studied in two niobium bearing nickel base superalloys—INCONEL 718 and INCONEL* 625—both of which are hardenable by the precipitation of the metastableγ″-Ni3Nb phase. The morphology and the distribution of precipitates have been examined and the crystallographic orientation relationship between the austenite . The fatigue test samples of high cycle fatigue (HCF) and low cycle fatigue (LCF) were traditional round bars and designed on ASTM E466 and ASTM E606, respectively, as shown in Figure 1. All fatigue tests were carried out by the MTS647 Hydraulic Wedge Grip microcomputer controlled electro-hydraulic servo testing machine with a computer .

nickel in delta phase

ni3nb temperature control

13 de fev. de 2024 · Fique por dentro de tudo que acontece no mundo do CartolaFC e no Mix! Seja sócio: https://cartolafcmix.com/planos

hardness test on deltaphase ni3nb|ni3nb delta phase